Guinea-Bissau Waste & Medical Waste Incinerator Market Report

Operational Review Across Bissau, Bafatá, Gabú, Cacheu, Bolama

1. Guinea-Bissau context: why incineration is a practical necessity

Guinea-Bissau is a small West African country with limited centralized infrastructure, a fragmented healthcare system, and strong reliance on international assistance and humanitarian programs. Waste management—especially medical waste and sensitive solid waste—faces structural constraints that make conventional landfill-based solutions unreliable.

Waste generation and institutional demand are mainly concentrated in:

-

Bissau – capital city, national hospitals, laboratories, ministries, UN and NGO offices

-

Bafatá and Gabú – eastern regional hubs with hospitals and cross-border health programs

-

Cacheu and Bolama – coastal and island areas with clinics, camps, and logistical challenges

In Guinea-Bissau, incineration is primarily used as a risk-mitigation and public health tool, ensuring safe destruction of waste streams that cannot be transported, stored, or treated safely by other means.

2. Structural characteristics of the Guinea-Bissau incinerator market

A. Medical waste as the dominant driver

The most consistent demand comes from:

-

public hospitals and regional clinics,

-

vaccination campaigns and laboratories,

-

NGO-operated health facilities.

Open dumping or uncontrolled burning remains a risk in many areas, making controlled incineration the preferred option in donor-backed and UN-supported projects.

B. Logistics constraints favor mobility

Poor road conditions, seasonal flooding, and island geography (notably Bolama) make waste transport difficult. This directly increases interest in:

-

on-site incineration,

-

containerized and mobile systems that can be relocated or shared between facilities.

C. Limited utilities and technical manpower

Buyers prioritize incinerators that:

-

operate on diesel fuel,

-

tolerate power instability,

-

require simple operator training.

3. City-based demand analysis

Bissau – National healthcare and institutional center

Bissau concentrates most of Guinea-Bissau’s healthcare and administrative infrastructure. Incinerators here are mainly required for:

-

infectious medical waste,

-

pharmaceutical disposal,

-

secure destruction of institutional waste.

Projects linked to international organizations often specify dual-chamber incinerators with documented operating parameters and basic emission control.

Bafatá & Gabú – Regional healthcare demand

These cities serve large rural populations and cross-border health initiatives. Waste volumes are moderate but continuous. Top-loading incinerators are favored due to:

-

simple feeding of bagged waste,

-

low maintenance requirements,

-

minimal civil works.

Cacheu & Bolama – Coastal and island challenges

In these regions, incinerators are often deployed to avoid long-distance transport to Bissau. Containerized mobile incinerators offer a decisive advantage by allowing:

-

rapid deployment,

-

operation in confined sites,

-

future relocation as programs evolve.

4. Role of the United Nations and international institutions

In Guinea-Bissau, United Nations agencies and international NGOs are central actors in waste management projects, especially in healthcare.

Their influence shapes:

-

technical specifications,

-

procurement standards,

-

training and documentation requirements.

Programs associated with UNDP, WHO, UNICEF, and other UN frameworks typically require:

-

safe destruction of infectious waste,

-

operator safety procedures,

-

reliable performance under low-infrastructure conditions.

This environment favors robust, conservative incinerator designs over complex or highly customized systems.

5. Market demand trends in Guinea-Bissau

-

Medical waste incineration will remain the primary demand segment nationwide.

-

Containerized and mobile incinerators are increasingly preferred due to logistics and island geography.

-

Buyers value modular systems that can be expanded or relocated as programs change.

-

Emission control is addressed pragmatically, focusing on functional compliance rather than advanced multi-stage treatment.

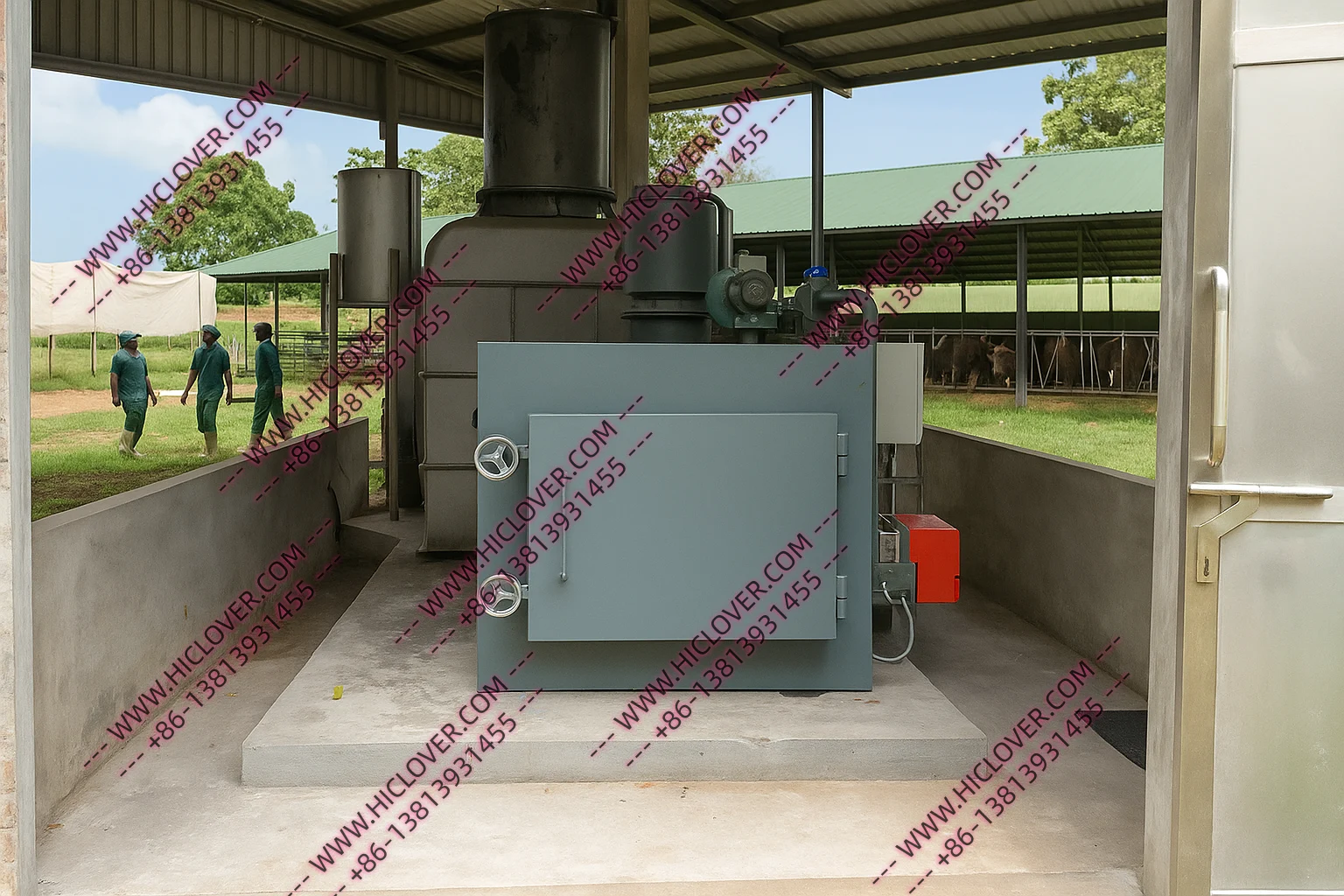

6. Product–market fit: HICLOVER solutions for Guinea-Bissau

HICLOVER incinerators align closely with Guinea-Bissau’s operational constraints, especially through mobile, containerized, and modular configurations:

-

Medical waste incinerators for hospitals and UN-supported facilities

Suitable for Bissau, Bafatá, and Gabú.

→ Medical Waste Incinerator Systems

https://www.hiclover.com/medical-waste-incinerator/ -

Top-loading incinerators for mixed medical and institutional waste

Effective where segregation is limited and simplicity is essential.

→ Top-Loading Waste Incinerators

https://www.hiclover.com/top-loading-incinerator/ -

Containerized mobile incinerators (key advantage for Guinea-Bissau)

Ideal for coastal and island deployments such as Cacheu and Bolama.

→ Containerized Mobile Incinerators

https://www.hiclover.com/containerized-mobile-incinerators/ -

Optional modular flue-gas treatment systems

Applied selectively in urban Bissau or donor-sensitive projects.

→ Incinerator with Wet Scrubber System

https://www.hiclover.com/incinerator-with-1-or-3-section-type-wet-scrubber/

Key advantage in Guinea-Bissau:

HICLOVER emphasizes containerized mobility, modular assembly, diesel compatibility, and rapid deployment, making its incinerators well suited to Guinea-Bissau’s fragmented infrastructure and donor-driven healthcare landscape.

7. Strategic theme highlight: “Mobile incineration for coastal and low-infrastructure states”

A strong positioning theme for Guinea-Bissau is:

“Mobile, containerized incineration for fragile coastal and island environments.”

This theme reflects real procurement logic:

-

infrastructure cannot be assumed,

-

programs evolve quickly,

-

reliability and relocation matter more than scale.

It resonates with healthcare administrators in Bissau, regional authorities in Bafatá, and UN project managers operating across Guinea-Bissau.

Résumé en français (bref)

En Guinée-Bissau, l’incinération est essentielle pour la gestion des déchets médicaux et des déchets sensibles, notamment à Bissau, Bafatá, Gabú, Cacheu et Bolama. Les Nations Unies et les ONG internationales jouent un rôle clé dans la définition des besoins et des normes. Les solutions mobiles, containerisées et modulaires sont particulièrement adaptées aux contraintes logistiques et insulaires du pays. Les incinérateurs HICLOVER répondent efficacement aux réalités opérationnelles du marché bissau-guinéen.

2025-12-13/22:18:39

|

Incinerator Items/Model |

HICLOVER TS100(PLC)

|

|

Burn Rate (Average) |

100kg/hour |

|

Feed Capacity(Average) |

150kg/feeding |

|

Control Mode |

PLC Automatic |

|

Intelligent Sensor |

Continuously Feeding with Worker HICLOVER |

|

High Temperature Retention(HTR) |

Yes (Adjustable) |

|

Intelligent Save Fuel Function |

Yes |

|

Primary Combustion Chamber |

1200Liters(1.2m3) |

|

Internal Dimensions |

120x100x100cm |

|

Secondary Chamber |

600L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Manual |

|

Burner Type |

Italy Brand |

|

Temperature Monitor |

Yes |

|

Temperature Thermometer |

Corundum Probe Tube, 1400℃Rate. |

|

Temperature HICLOVER |

Yes |

|

Automatic Cooling |

Yes |

|

Automatic False Alarm |

Yes |

|

Automatic HICLOVER Operator(APO) |

Yes |

|

Time Setting |

Yes |

|

Progress Display Bar |

3.7 in” LCD Screen |

|

Oil Tank |

200L |

|

Chimney Type |

Stainless Steel 304 |

|

1st. Chamber Temperature |

800℃–1000℃ |

|

2nd. Chamber Temperature |

1000℃-1300℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

7000kg |

|

External Dimensions |

270x170x190cm(Incinerator Main Body) |

|

Burner operation |

Automatic On/Off |

|

Dry Scrubber |

Optional |

|

Wet Scrubber |

Optional |

|

Top Loading Door |

Optional |

|

Asbestos Mercury Material |

None |

|

Heat Heart Technology(HHT) |

Optional |

|

Dual Fuel Type(Oil&Gas) |

Optional |

|

Dual Control Mode(Manual/Automatic) |

Optional |

|

Temperature Record |

Optional |

|

Enhanced Temperature Thermometer |

Optional |

|

Incinerator Operator PPE Kits |

Optional |

|

Backup Spare Parts Kits |

Optional |

|

Mobile Type |

Optional:Containerized/Trailer/Sledge Optional |