Low-Temperature Controlled Incineration Solutions for Electronics Manufacturing and Battery Recycling Facilities

The rapid expansion of the electronics manufacturing industry and lithium battery recycling sector has brought new challenges in managing complex industrial waste streams. From high-volume electronic assembly lines in East Asia and Southeast Asia, to emerging battery recycling workshops in Europe, North America, and South Asia, manufacturers are increasingly required to handle waste that is lightweight, mixed-material, and environmentally sensitive.

Unlike traditional municipal or medical waste, electronic manufacturing waste demands controlled thermal treatment, low secondary pollution risk, and compliance-oriented emission control. This is where low-temperature controlled incineration systems become a practical and forward-looking solution.

Typical Application Scenarios

In electronics and battery-related industries, incineration is not designed for bulk destruction, but for safe, localized, and compliant disposal of specific waste categories.

Common operating environments include:

-

Electronic assembly lines producing consumer electronics, PCB boards, and components

-

Lithium battery dismantling and pre-treatment workshops

-

R&D and pilot recycling facilities in industrial parks

-

Export-oriented electronics factories under strict ESG and environmental audits

These facilities are commonly found in regions such as China’s Pearl River Delta, Vietnam’s industrial zones, India’s electronics clusters, Eastern Europe, and Mexico’s manufacturing corridors, where waste transportation and off-site treatment are increasingly regulated.

Waste Characteristics in Electronics & Battery Recycling

The waste streams generated in these environments are diverse and require careful handling:

-

Anti-static fabrics and wipes used in cleanrooms and assembly lines

-

Plastic films and packaging materials contaminated with residues

-

Small lithium batteries and electronic components with chemical sensitivity

These materials typically feature:

-

Low to medium calorific value

-

Risk of acid gas release during combustion

-

Potential for secondary pollution if burned at uncontrolled temperatures

As a result, standard high-temperature incinerators are often unnecessary or unsuitable for this application.

Low-Temperature Controlled Incinerator Configuration

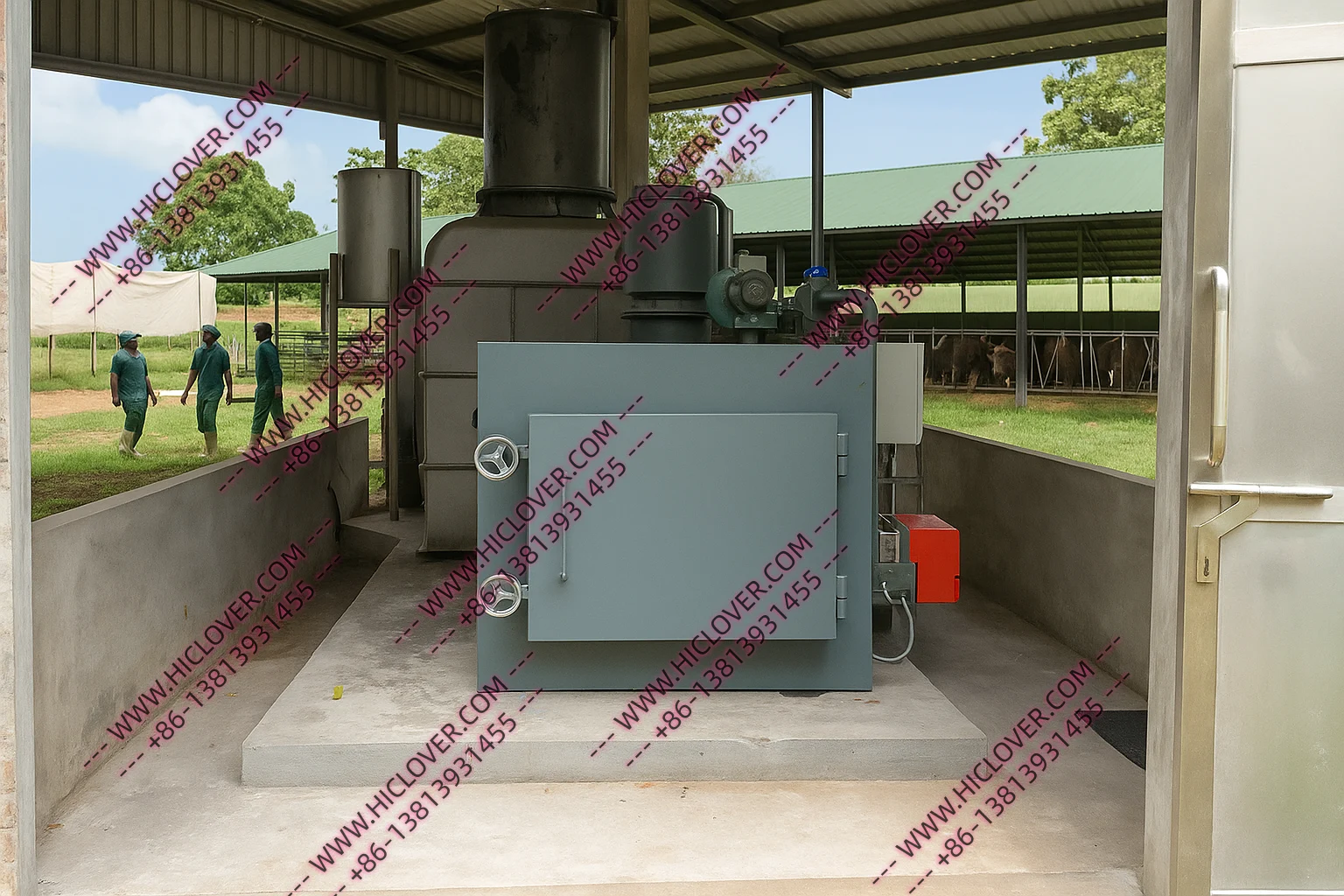

HICLOVER designs low-temperature controlled waste incinerators specifically for industrial environments where precision and emission control matter more than sheer capacity.

Key configuration logic includes:

-

Controlled combustion temperature to avoid excessive volatilization of harmful compounds

-

Stable primary combustion for plastic films, anti-static materials, and light industrial waste

-

Secondary flue gas treatment using an acidCalkali scrubber system, minimizing the release of acidic gases

-

Compact and modular layout, suitable for installation near production or recycling workshops

This configuration supports on-site disposal, reducing dependence on external waste handlers and improving traceability.

More details on industrial incineration systems can be found at

https://www.hiclover.com/

Preventing Secondary Pollution

One of the core concerns in battery recycling and electronics waste disposal is secondary pollution―especially acidic exhaust, odor, and fine particulates.

A properly configured low-temperature incineration system integrates:

-

Gas quenching and cooling stages

-

AcidCalkali washing towers to neutralize corrosive components

-

Controlled airflow and negative pressure operation

This design approach aligns with environmental compliance expectations in regions such as the EU, Middle East, and OECD-regulated industrial zones, where electronics manufacturers are under increasing scrutiny.

Learn more about modular industrial waste solutions at

https://www.hiclover.com/industrial-waste-incinerator/

Why On-Site Incineration Is Gaining Attention

For electronics manufacturers and battery recycling operators, on-site incineration offers several structural advantages:

-

Reduced transportation and outsourcing costs

-

Improved waste handling security and audit readiness

-

Faster response to production fluctuations

-

Long-term operational stability

This is particularly relevant for export-oriented factories, free-trade zones, and remote industrial parks, where waste logistics are costly or tightly regulated.

HICLOVER’s approach emphasizes factory-side deployment, modular delivery, and simplified operation logic―making the system adaptable to both mature industrial regions and fast-growing manufacturing hubs.

Additional system overviews are available at

https://www.hiclover.com/waste-incinerator/

A Practical Direction for the Electronics Industry

As electronics manufacturing and lithium battery recycling continue to expand globally, waste treatment solutions must evolve accordingly. Low-temperature controlled incineration, combined with acidCalkali gas scrubbing, represents a balanced and forward-compatible approach―addressing environmental responsibility without adding unnecessary complexity.

For manufacturers seeking a stable, compliant, and localized waste disposal solution, this configuration offers a clear technical direction aligned with modern industrial standards.

Explore more application-specific incineration solutions at

https://www.hiclover.com/solutions/

Keywords naturally embedded: electronics manufacturing waste incinerator, battery recycling waste disposal, low temperature controlled incinerator, industrial incineration system, on-site waste treatment, acid alkali scrubber incinerator