Nigeria Waste Incinerator Market Report: Characteristics, Demand Trends, and Equipment Adaptation

Nigeria’s rapid urbanization and expanding industrial base have reshaped the country’s waste management landscape. Major cities such as Lagos, Abuja, Port Harcourt, Kano, and Ibadan now generate significantly more municipal, medical, and industrial waste than existing disposal systems can handle. As a result, the need for reliable waste incinerators has grown into a structural national demand rather than a temporary infrastructure gap.

Market Characteristics in Nigeria

Several factors define Nigeria’s waste management environment:

-

High population density in Lagos and Kano, driving high-volume municipal waste generation.

-

Large healthcare and laboratory networks, especially in Abuja and Port Harcourt, which create continuous streams of biomedical waste requiring controlled high-temperature treatment.

-

Significant agro-industrial waste, including poultry, fishery, and abattoir residues around Ogun State, Oyo State, Kaduna, and Enugu.

-

Insufficient landfill capacity and informal dumping, pushing both government and private operators to seek thermal treatment alternatives.

-

Coastal and riverine environments, such as in Bayelsa and Rivers State, where moisture-rich waste and humid climates demand robust, corrosion-resistant equipment.

These characteristics shape the equipment requirements for both small facilities and large public waste authorities across Nigeria.

Market Demand and Trends

Nigeria’s incinerator demand is rising along three major pathways:

• Medical waste management compliance – Hospitals in Lagos, Abuja, and Kano increasingly face pressure to adopt high-temperature incineration to meet sanitary and environmental expectations.

• Decentralized municipal solutions – Local councils in states like Edo, Delta, and Akwa Ibom often prefer compact or containerized systems that avoid long waste transportation routes.

• Industrial and agricultural sector needs – Slaughterhouses, poultry farms, food processors, and oil & gas service bases in Port Harcourt and Warri seek efficient treatment for organic and hazardous residues.

A strong emerging trend is the adoption of mobile and containerized incinerator units, which provide rapid deployment and are highly suited to multi-location operations across diverse Nigerian regions.

Suitability of Incinerators for Local Nigerian Conditions

Waste streams in Nigeria are typically mixed, containing plastics, organics, moisture-heavy kitchen waste, and hospital disposables. Equipment must therefore provide:

-

High combustion temperature stability

-

Fuel-efficient burners suitable for diesel or gas

-

Durable refractory lining for continuous high-load operation

-

Ease of maintenance, due to limited technical infrastructure in secondary cities

-

Adaptability to humid coastal climates

-

These requirements make ruggedized, dual-chamber and container-ready units especially appropriate.

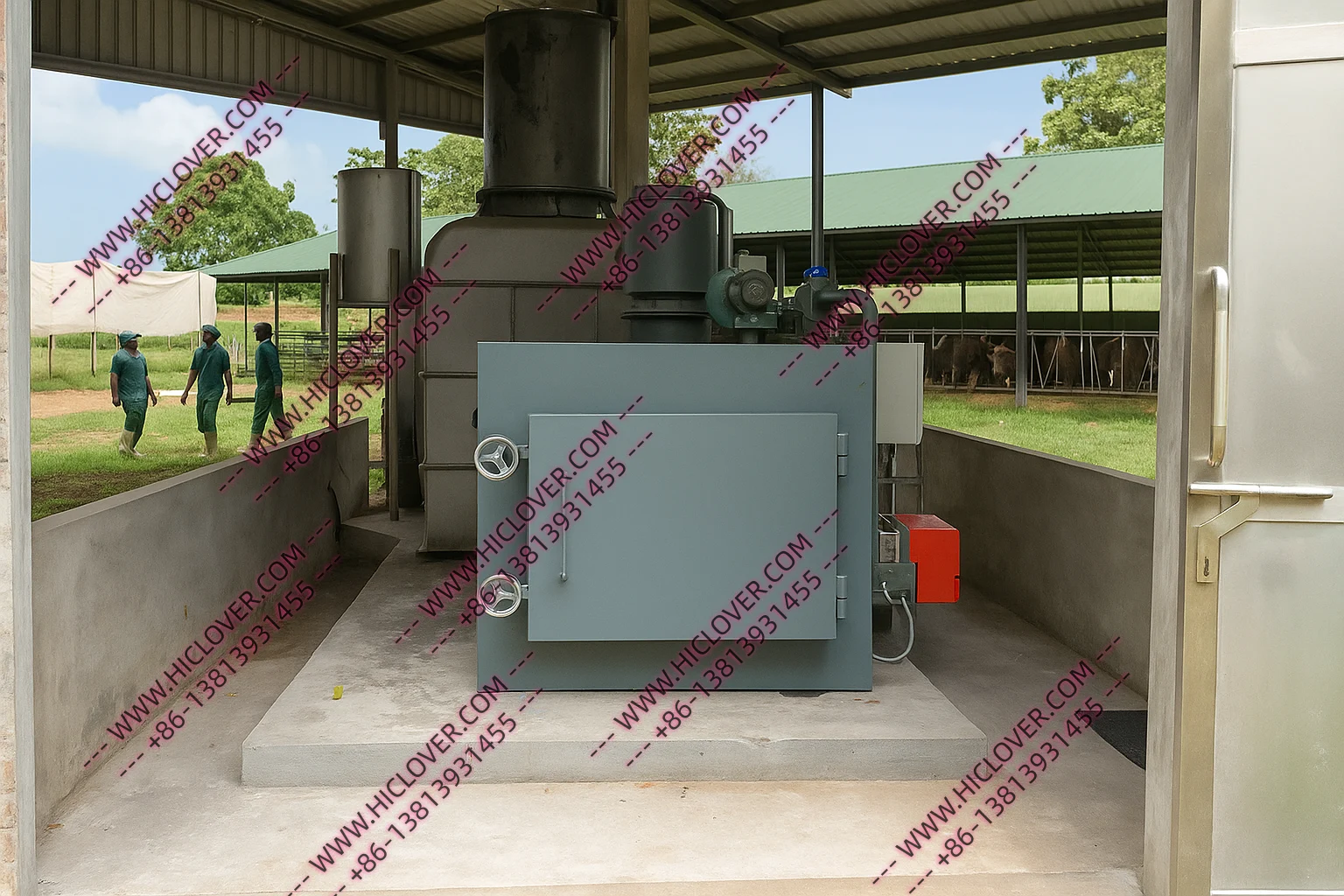

HICLOVER Incinerators in the Nigerian Market

HICLOVER equipment aligns directly with Nigeria’s operational realities and market expectations. A randomly emphasized theme—efficiency under high waste diversity—helps illustrate why such systems perform well across the country.

Key advantages include:

-

Heavy-duty dual combustion chambers, allowing complete oxidation of smoke and fumes, which is important in dense urban areas such as Lagos Mainland, Surulere, and Ikeja.

-

Top-loading and side-loading options, suitable for bulky municipal bags, medical containers, and agro-waste batches common in Abuja, Kano, and Port Harcourt.

-

Containerized plug-and-play deployment, ideal for rural medical centers, temporary field clinics, and oil & gas support bases in Rivers State, Bayelsa, and Cross River.

-

Low installation requirements, allowing quick setup even in remote towns like Maiduguri or Sokoto.

-

Stable long-term operation, supported by reinforced refractories and reliable burners that maintain temperature despite moisture and mixed composition.

The combination of structural durability, high-temperature performance, and flexible integration makes HICLOVER’s systems highly suitable for both government facilities and private-sector operators across Nigeria.

Additional Focus Theme: Oil & Gas Sector Waste Handling

Nigeria’s vast oil & gas operations around Port Harcourt, Bonny Island, Warri, and Eket generate specialized solid wastes that require safe on-site destruction. Many operators prefer mobile incinerators that can be relocated between drilling sites or FPSO support bases. High-temperature chambers with minimal civil works provide a pragmatic solution, reducing logistics costs and ensuring immediate waste treatment compliance. HICLOVER’s containerized and skid-mounted units integrate effectively into such industrial environments.

Market Outlook

Nigeria’s waste incinerator market is expected to grow steadily, driven by rising environmental regulations, healthcare expansion, and increasing scrutiny from international stakeholders. Urban and peri-urban centers will continue investing in systems capable of handling medical waste, municipal solids, and agricultural residues.

Nigeria presents one of the most dynamic waste incineration markets in West Africa. From Lagos to Abuja, Port Harcourt to Kano, the need for dependable thermal treatment technologies is expanding across healthcare, municipal, industrial, and oil & gas sectors. HICLOVER incinerators offer a robust match to these conditions, providing strong combustion performance, adaptable configurations, and long-term reliability tailored to Nigeria’s diverse waste challenges and operational environments.

2025-12-11/08:44:31

|

Incinerator Items/Model |

HICLOVER TS100(PLC)

|

|

Burn Rate (Average) |

100kg/hour |

|

Feed Capacity(Average) |

150kg/feeding |

|

Control Mode |

PLC Automatic |

|

Intelligent Sensor |

Continuously Feeding with Worker HICLOVER |

|

High Temperature Retention(HTR) |

Yes (Adjustable) |

|

Intelligent Save Fuel Function |

Yes |

|

Primary Combustion Chamber |

1200Liters(1.2m3) |

|

Internal Dimensions |

120x100x100cm |

|

Secondary Chamber |

600L |

|

Smoke Filter Chamber |

Yes |

|

Feed Mode |

Manual |

|

Burner Type |

Italy Brand |

|

Temperature Monitor |

Yes |

|

Temperature Thermometer |

Corundum Probe Tube, 1400℃Rate. |

|

Temperature HICLOVER |

Yes |

|

Automatic Cooling |

Yes |

|

Automatic False Alarm |

Yes |

|

Automatic HICLOVER Operator(APO) |

Yes |

|

Time Setting |

Yes |

|

Progress Display Bar |

3.7 in” LCD Screen |

|

Oil Tank |

200L |

|

Chimney Type |

Stainless Steel 304 |

|

1st. Chamber Temperature |

800℃–1000℃ |

|

2nd. Chamber Temperature |

1000℃-1300℃ |

|

Residency Time |

2.0 Sec. |

|

Gross Weight |

7000kg |

|

External Dimensions |

270x170x190cm(Incinerator Main Body) |

|

Burner operation |

Automatic On/Off |

|

Dry Scrubber |

Optional |

|

Wet Scrubber |

Optional |

|

Top Loading Door |

Optional |

|

Asbestos Mercury Material |

None |

|

Heat Heart Technology(HHT) |

Optional |

|

Dual Fuel Type(Oil&Gas) |

Optional |

|

Dual Control Mode(Manual/Automatic) |

Optional |

|

Temperature Record |

Optional |

|

Enhanced Temperature Thermometer |

Optional |

|

Incinerator Operator PPE Kits |

Optional |

|

Backup Spare Parts Kits |

Optional |

|

Mobile Type |

Optional:Containerized/Trailer/Sledge Optional |